Liquid Salt Purification

Advanced High Temperature Reactors (AHTRs) use clean fluoride salts as coolants for solid, high-temperature TRISO fuel. Because AHTRs have fully ceramic cores, they can operate safely at substantially higher temperatures and higher power conversion efficiencies than conventional water-cooled and sodium-cooled reactors with metal-clad fuels.

The most recent baseline AHTR designs operate with a core inlet temperature of 600°C and outlet temperature of 704°C, giving 46% power conversion efficiency. For AHTR reactor designs, conventional Alloy 800H provides an excellent near-term structural material [Caron et al., 2008].

Alloy 800H is also used extensively in the chemical and fossil industries, and is ASME Section III code qualified for use in nuclear systems at temperatures up to 760°C. The current baseline primary coolant for the AHTR is 7Li2BeF4 (flibe), which enables core designs with negative coolant void reactivity and with excellent fuel utilization. However, current purification methods require the use of toxic HF gas, which is costly to handle and is accompanied by severe safety constraints. Salt heat transfer systems will require both initial cleaning and an online chemistry control system to maintain the purity of the salt to limit corrosion and deposition and fouling problems. NF3 has the potential to replace the HF gas purification with substantially reduced costs and safety implications.

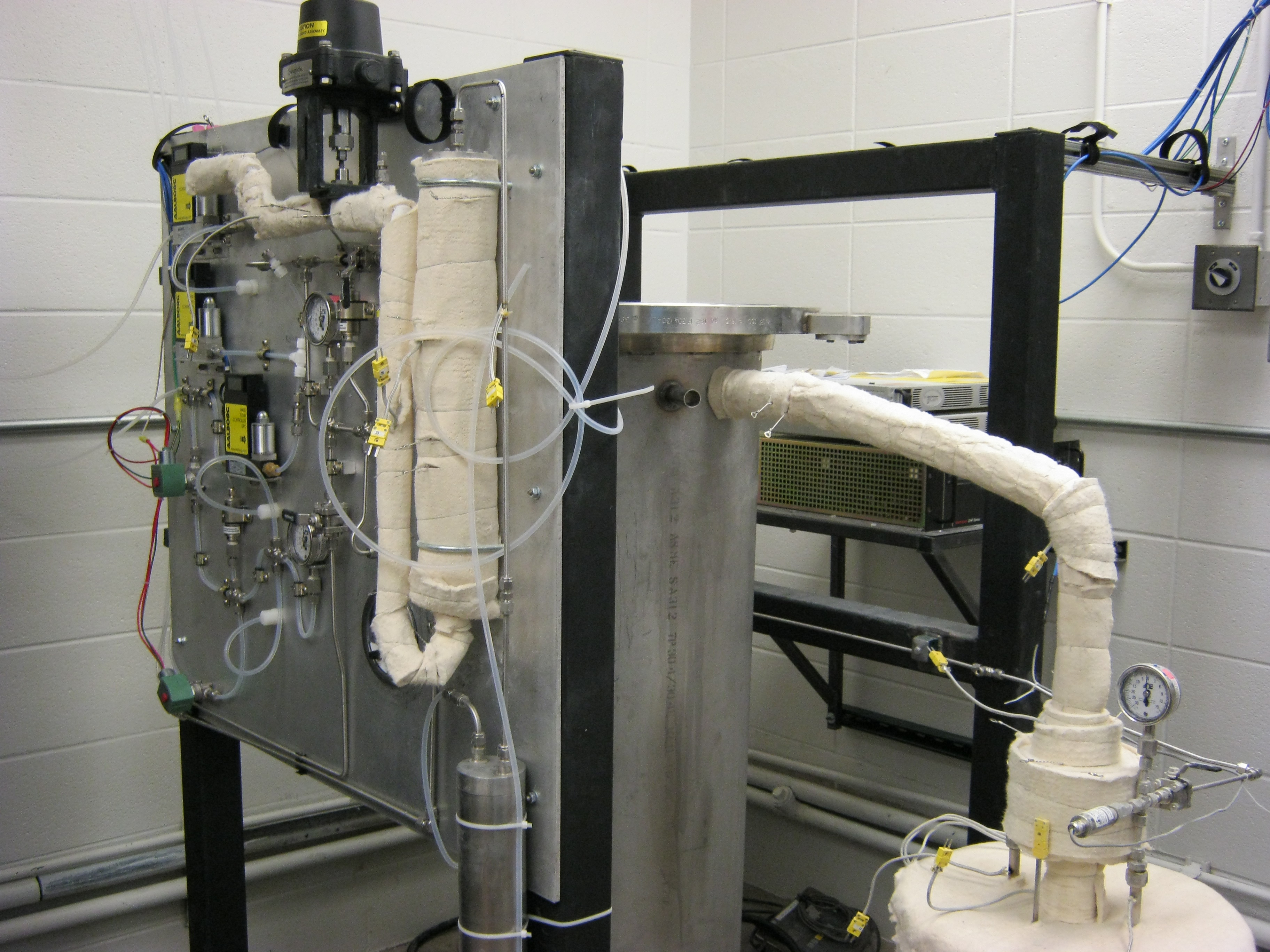

The Inert Environment FLiBe Liquid Salt Handling Facilty and the High Temperature Liquid Salt Chemical Purification System are used to study the purification process and obtain salts for corrosion testing.